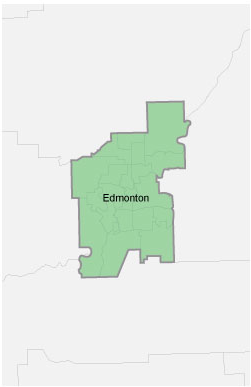

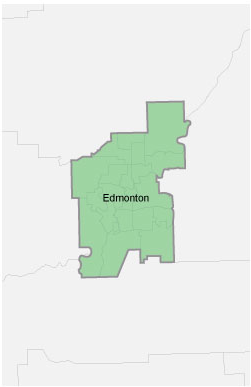

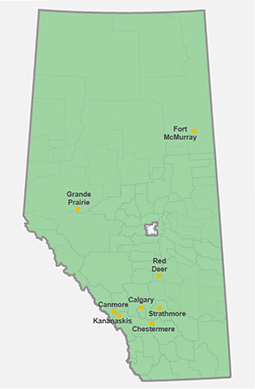

Serving Edmonton and surrounding areas for over 100 years

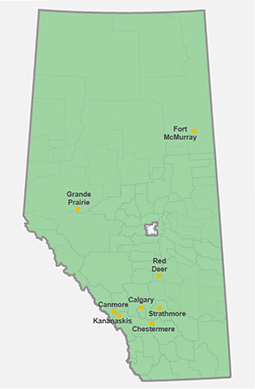

The Rossdale site is located in Edmonton's North Saskatchewan River valley, close to the Walterdale Bridge. The 36.4 acre (14.7 hectare) facility is a well-known historical site in the heart of the city. The Rossdale site has been providing water and power to Edmonton citizens for more than 100 years. Today, the site supplies Edmonton and its surrounding areas with drinking water and power.

About the Rossdale site

The Rossdale site includes the Rossdale and Bellamy Substations, the Rossdale Water Treatment Plant, a guardhouse, and other EPCOR-owned facilities. The Rossdale Water Treatment Plant has been in operation in Edmonton since 1903. The current plant was built in 1947 and expanded in 1956.

Rossdale and Bellamy Substations

A substation is a part of the electrical system that connects two or more powerlines. The Rossdale and Bellamy substations convert electricity from higher voltage (power lines transmission lines) to lower voltages that can be safely distributed to homes and businesses in the area.

Rossdale Water Treatment Plant

The Rossdale Water Treatment Plant is one of Edmonton's two water treatment plants, and has been providing water to citizens of Edmonton since 1903. Water from the North Saskatchewan River is treated, tested and stored on-site in reservoirs until is needed. Clean drinking water is then pumped out through the transmission/distribution system to homes and businesses throughout the city.

Historical significance

We recognize the archaeological and historical significance of the site: the importance of this area in fostering communities predates the City of Edmonton itself. As such, we are committed to preserving the heritage and history of Rossdale, providing more open and public space and minimizing impacts to the community. To ensure the integrity of this area, all excavations completed on site will be appropriately managed. When appropriate an archaeologist of record will be on site during ground disturbances.